New implants for patients with thoracic malformations

Over the course of two years, a human being takes around 16 million inhalations and exhalations. By testing chest-correcting implants on artificial ribs, researchers at the Łukasiewicz – Poznan Institute of Technology are speeding up this process, reducing it to one month. This is all so that patients with chest deformities can live more comfortably after surgery with these implants.

The thoracic correction implant is an elongated, slightly curved plate made of steel. It is quite long, like the span of the patient’s ribs, and terminates in attachments that screw onto the ribs.

Who are these implants for?

These implants are used to correct two defects. The first is a funnel-shaped chest (also known as a suture chest). It is characterised by a collapse of the lower part of the sternum. In most cases it is an aesthetic problem, but sometimes it can put pressure on the heart and lungs. As a consequence, the patient has a reduced lung capacity, tolerates exertion poorly, may have breathing problems or impaired heart valve function.

The second deformity is called chicken chest and involves the sternum and adjacent ribs protruding forward, somewhat resembling a bird’s rib cage. Because it causes a reduction in the mobility of the ribs, a person with a chicken chest may also have difficulty breathing.

Implant and twist

There are various methods of treating these defects, but the most effective is surgery. In the case of a funnel-shaped defect, this involves doctors inserting a steel implant under the ribs, rotating it 180 degrees so that it aligns the sternum and ribs, and attaching its ends to the ribs. After two years, the implant is removed.

Until now, implants have been attached using a wire, which was uncomfortable and painful for patients. This is why a new implant has been developed by BHH Mikromed, the AGH University of Science and Technology and Łukasiewicz – Poznan Institute of Technology in cooperation with surgeons from the Department of Paediatric Malformation Surgery and Traumatology at the Silesian Medical University in Zabrze. It will be used to correct both defects.

The new implant eliminates the wire, replacing it with stainless steel ‘paws’ with which the rib is grasped and fixed, pressing the screw in place accordingly. The rib is not drilled. The new implant will hold firmly, so it will not damage the ribs, tissues or organs. Wearing it will be more stable, more comfortable and, above all, less painful.

Tests on artificial ribs

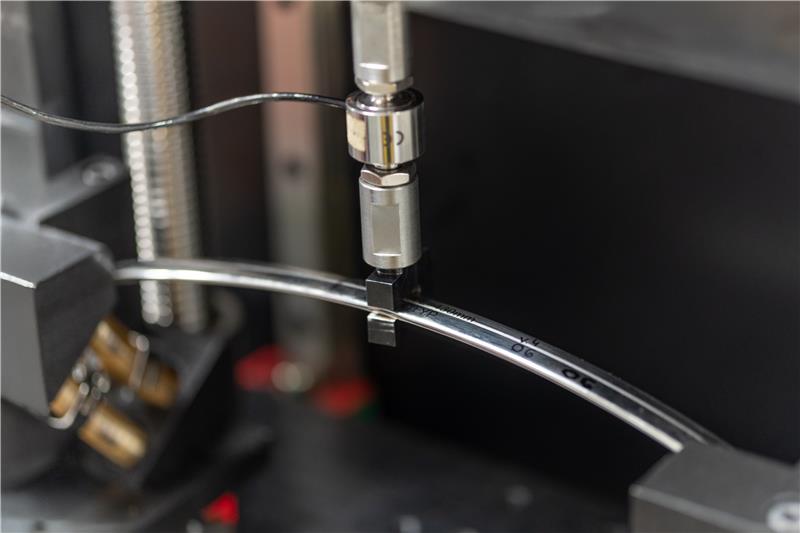

However, before an implant is placed in anyone, it has to undergo meticulous tests. These take place at Łukasiewicz – PIT, and ten different implant sizes are subjected to them. Researchers have constructed a special stand in which the implant attached to the 3D-printed ribs is pressed with the same force as human ribs work when breathing.

– We check how the material behaves: whether it does not crack, whether its surface does not change, whether it does not slip out of the ribs, whether the screws of the implants still hold firmly,’ explains Joanna Sulej-Chojnacka, PhD, from Łukasiewicz – PIT. – ‘We subject the implant to 16 million pressures per month, which corresponds to the number of inhalations and exhalations a person does over two years. After these fatigue tests, we still analyse each implant under a microscope to pick up changes invisible to the naked eye,’ she adds.

The tests are expected to last until the end of the year. There is therefore a chance that the new implants will already be in operating theatres next year.